Automotive Conveyors

Automotive Industry Case History

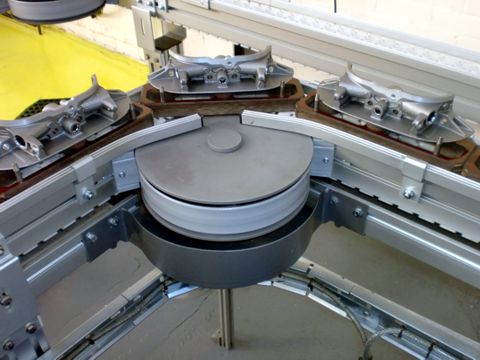

Dawson Shanahan in Welshpool are specialists in precision cold forming and machining. They approached Monk Conveyors for an automotive conveyor system to transport machined car parts from a CNC machine to a Wash Machine.

Monk helped design the base of a small pallet 280 x 80mm to hold the parts. Pneumatic gates were installed to allow parts to stop in front of operator stations. Due to coolant being present on the parts, a full conveyor drip tray with drainpipes was fitted to the conveyor system.

Modu System MM 85mm wide conveyor system was used. The automotive project included full mechanical and electrical installations, followed by training and handover to the customer.