FlexChain Conveyors

MONK Conveyors is an Approved System Builder for MODU System plastic chain conveyors and has built and installed a variety of modular systems since 2007.

MODU offer a high quality, robust and cost-effective flexible chain conveyor system. Over the last 25 years, MODU has expanded its operation to the United States, China, Australia, India, Indonesia, Singapore and Malaysia. We are very pleased continue to be their key partner in the United Kingdom and Europe.

MODU offer a high quality, robust and cost-effective flexible chain conveyor system. Over the last 25 years, MODU has expanded its operation to the United States, China, Australia, India, Indonesia, Singapore and Malaysia. We are very pleased continue to be their key partner in the United Kingdom and Europe.

MODU is used extensively in the Food and Packaging, Medical and Pharmaceutical, Automotive, Electronics and Optical industries. MONK Conveyors adds pneumatic and electrical control systems to provide customers turn-key solutions.

What is MODU? 60 Second Explainer

Flexible Conveyor System with Bends

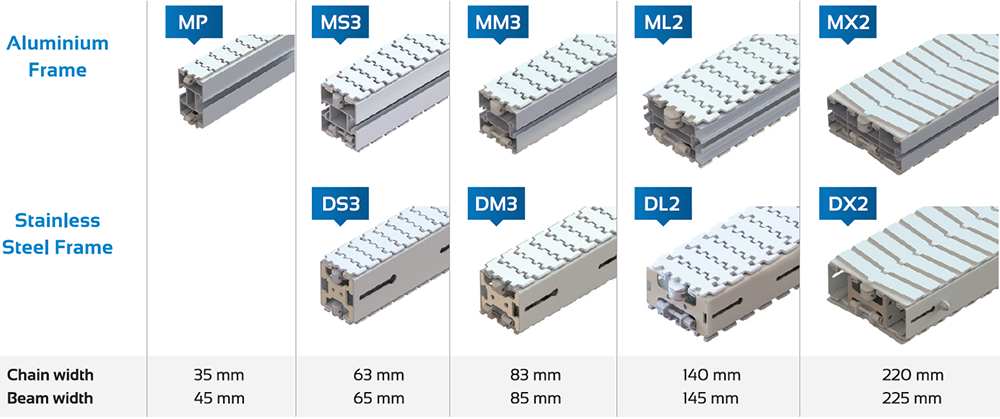

Standard chain material is acetal resin (POM) with the conveyor frame available in aluminium or stainless steel, which is selected depending on the customer environment.

Aluminium chain conveyors are based on an anodized aluminium beam fitted with low friction slide rail which precisely guides the flexible MODU plastic chain. Tight radius wheel bends and larger radius plain bends mean products, large and small can be carried around both horizontal and vertical conveyor bends. Bends start at 150mm radius with bend angles of 30, 45, 90 and 180. Attachments are added to the chain enabling products to be carried up inclines or gripped and lifted vertically. Guide rails on the sides of the conveyor make sure that the products stay on track. For more information about our fliexble chain conveyors, send us a message or give us a call.

Plain Chain

High Friction Chain

Finger Gripper Chain

Box Gripper Chain

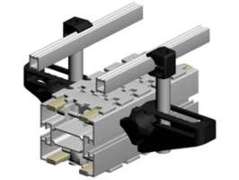

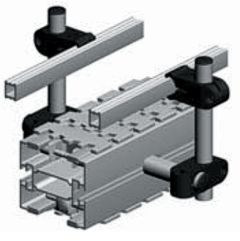

Standard Drive Unit

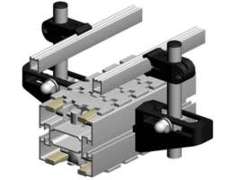

Suspended Drive Unit

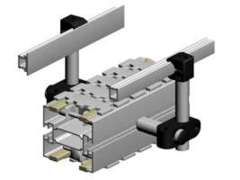

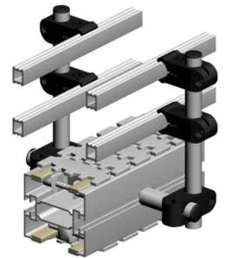

Combined Drive Unit

Idler End

Standard Drive Units

Pull the chain from one end of the modular conveyor. The chain returns on the bottom of the conveyor beam, passing through an idler end at the other end.

Suspended Drive Units

The motor is positioned below the drive. This kind of drive is applicable when the conveyors are placed side by side, or when feeding into a machine.

Combined Drive Units

Those that have a drive unit and an idler end together in one unit. This is used in areas where transfer from drive unit of one chain conveyor to another of the same size is required. The transfer area is provided with steel plate, gravity transfer rollers or powered transfer rollers depending on product type and length.

Idler End

Use to change the direction of the chain with minimum amount of friction. It is positioned at one end of the conveyor.

Intermediate Drive Units

Located at an intermediate point of the chain conveyor, having an idler end at both ends of the conveyor.

Catenary Drive Units

Used in applications where chain running on the bottom track is either not desired or not possible. e.g.: closed loop conveyor.

Modular Chain Conveyor Bends

Horizontal Wheel Bend

Horizontal Plain Bend

Vertical Bend

Horizontal Wheel Bend

The bend force is taken by the free running wheel of a horizontal wheel bend. The smallest radius and the lowest friction is also achieved.

Horizontal Plain Bend

For a larger radius a horizontal plain bend is used.

Vertical Bend

To achieve a change of direction vertically for chain conveyor inclines and declines.

Chain Conveyor Guides

Type 1

Type 2

Type 3

Type 4

Type 5

Type 6

Modular Conveyor Supports

Type 1 Single leg stand

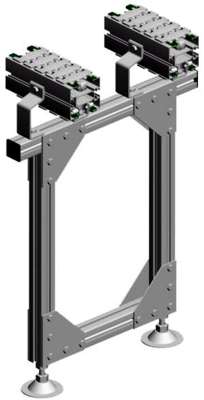

Type 2 Twin leg stand

Type 3 Hanging support