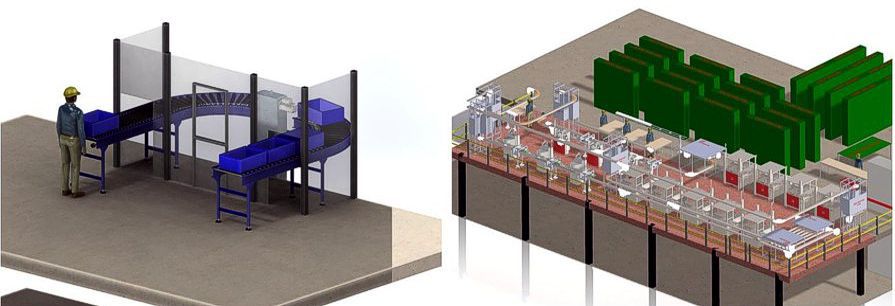

MONK has provided Conveyor Systems and Product handling solutions to a wide range of industries for over 25 years. Designing a warehouse handling system tailored specifically to your needs involves careful consideration of your product, operators, machine throughput and line capacity.

Our wide range of products and experience helps us work with you to meet all of your essential warehouse demands. We work with you to provide the best production solution to move materials and products around your factory. Our goal is to provide cost effective warehouse packing and sortation solutions with the highest level of service.

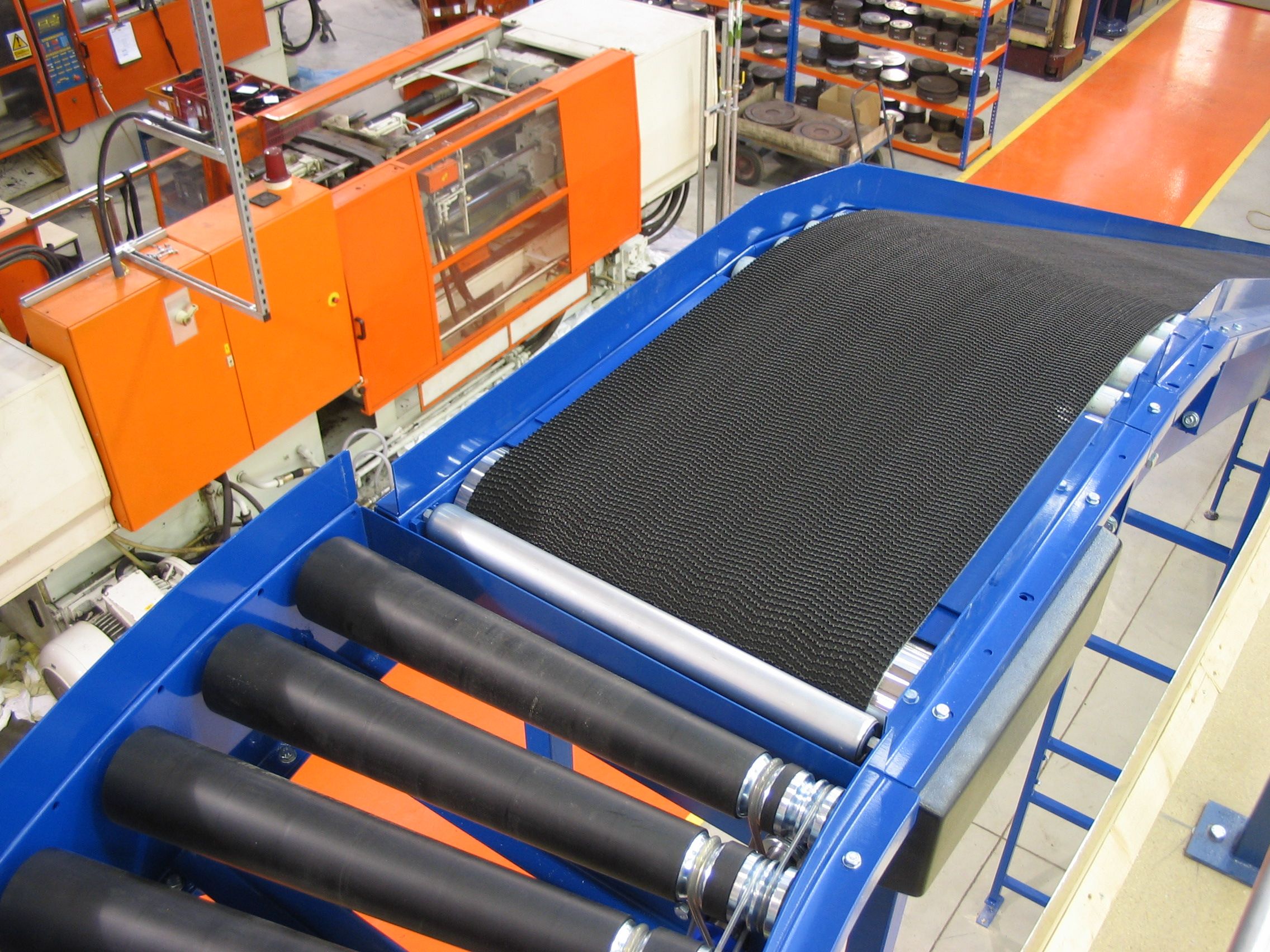

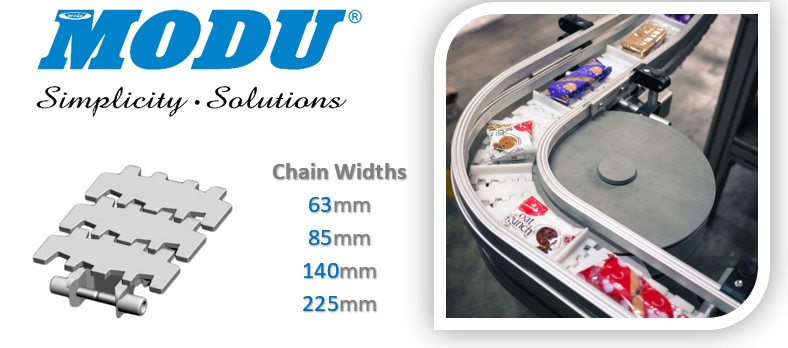

Our roller conveyors are a proven cost-efficient solution for the many meters of track used in handling and delivering totes and parcels in warehouses or packing halls. Pallets can also be handled on our special purpose pallet system, feeding to robots, wrappers or racking.

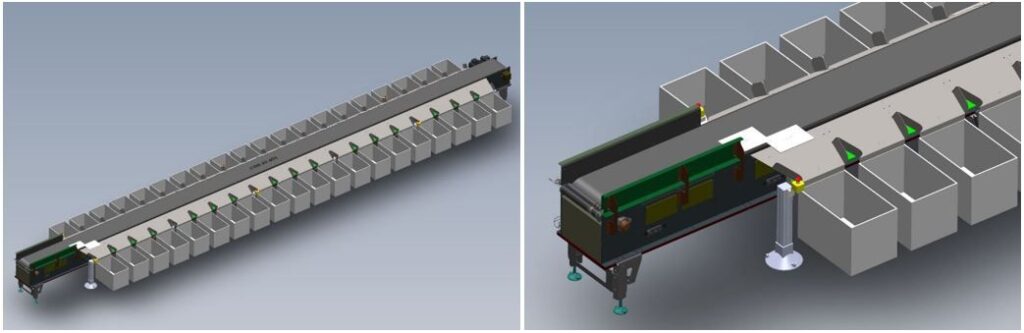

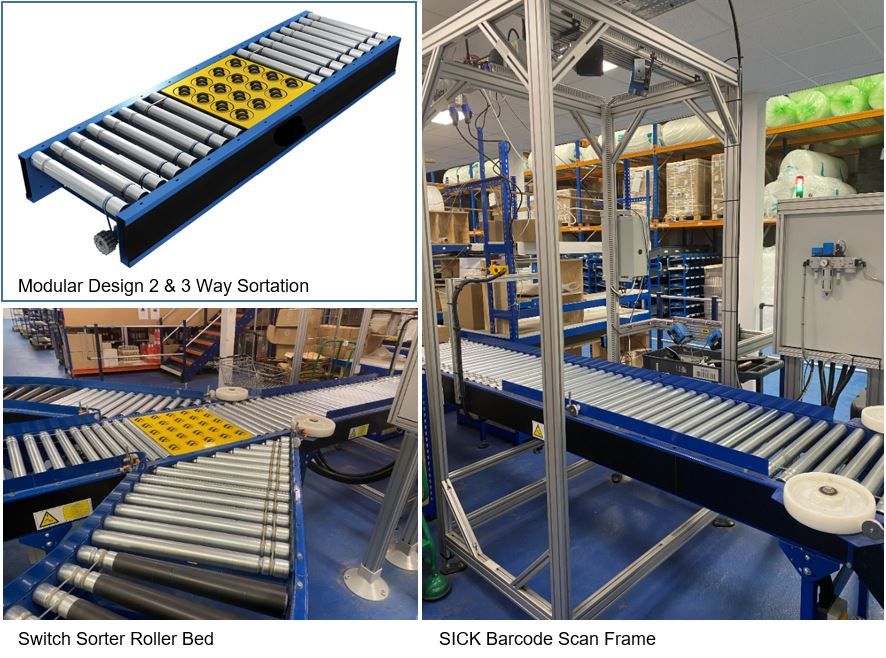

Our warehouse packing conveyor systems help to create efficient packing areas. Our systems are designed take up a small amount of floor space and allow multiple pack tables to sit on both sides of a central feed conveyor. Packers can randomly place product onto the conveyor which feeds work away. The system creates gaps between the product before feeding under a barcode unit. Monk Conveyors work with SICK and an OPS690 Scanning Rig is commonly used. This has the ability to scan product from multiple angles if required.

The right conveyor system in your warehouse can reduce manpower, improve accuracy and increase productivity. We will design you a product feed system completely tailored to your site. Monks range of conveyors means we can use standard equipment to reliably handle the size and shapes of your product range.

Barcode Data enables us to question the Warehouse Management System (WMS) and retrieve information which can be used to route product. Routing can be by product type, job number, size, pre-set flags or courier type and to several destinations.

The product is routed using a number of standard options including side belts, diverter arms, air blows and switch sorters as shown in this project. The switch sorter quickly diverts to one of three lanes without slowing the product down.

Touch Screen displays make it easier for operators to run a sortation system. Clear information is displayed and help screens can be added. Fault finding messages make it easier to find problems quickly.

Mimic screens show a graphical representation of the production line. They can then display the status of each part of the line by changing colour. If there is a blockage, a section of the line can be highlighted to show an operator the location of the problem. Screens can also allow operators to adjust the line settings and these can be password protected to ensure only trained personnel have access.

Remote access to the PLC and barcode systems means that we can dial in to make minor software changes and assist site with problem solving.

All systems are mechanically and electrically installed with full handover and training. Service and maintenance contracts can be provided along with critical spares.

We Also Supply Belt and Pallet Conveyors

Monk Conveyors supply and install full working systems which are designed to suit your specific needs. We install full pneumatic and electrical control with operator touch screens if required. Our control systems range from simple stop starts up to barcode capable controls, capable of communicating with your Warehouse Management System (WMS).

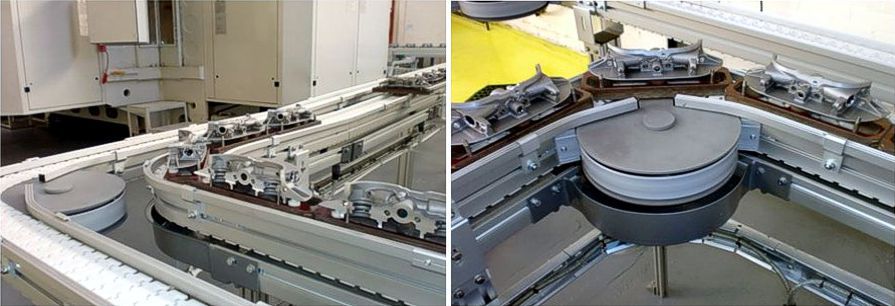

We are very proud to have worked with The Norville Group, delivering on all of their requirements for new lines across Surfacing, Coating and Glazing. Our knowledge of the Optical Industry and experience helped us to work with Nevil Trotter on completing their project on time and to the highest standard. Take a look for yourself in our video interview.