Automated Sortation System Case History

Atom Group is a pioneering global drinks group encompassing the global online retail website Master of Malt.

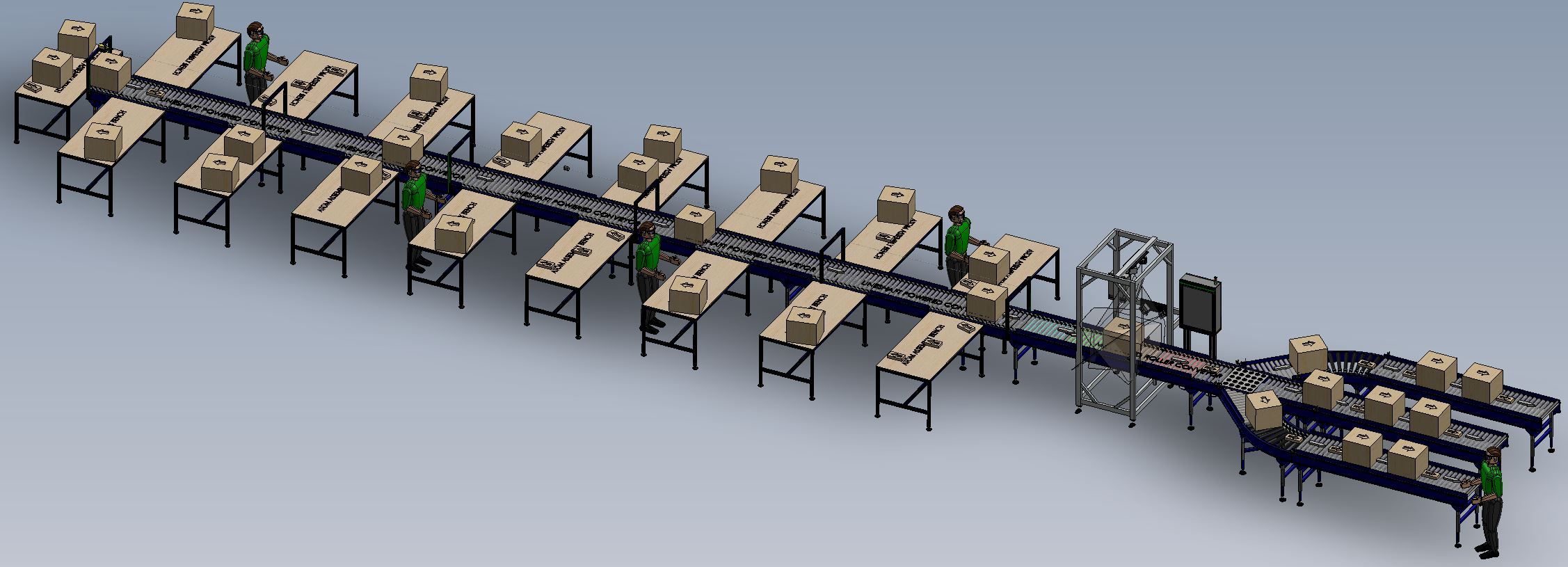

Our automated sortation systems help to create efficient packing areas. Systems take up a small floor space and allow multiple pack tables to sit on both sides of a central feed conveyor.

Packers can randomly place product onto the conveyor which feeds work away. The automated system creates gaps between the product before feeding under a barcode unit. Monk Conveyors work with SICK and a Scanning Rig is commonly used. This has the ability to scan product from multiple angles if required.

Barcode Data enables us to question the Warehouse Management System (WMS) and retrieve information which can be used to route product. Routing can be by product type, job number, size, pre-set flags or courier type and to a number of destinations.

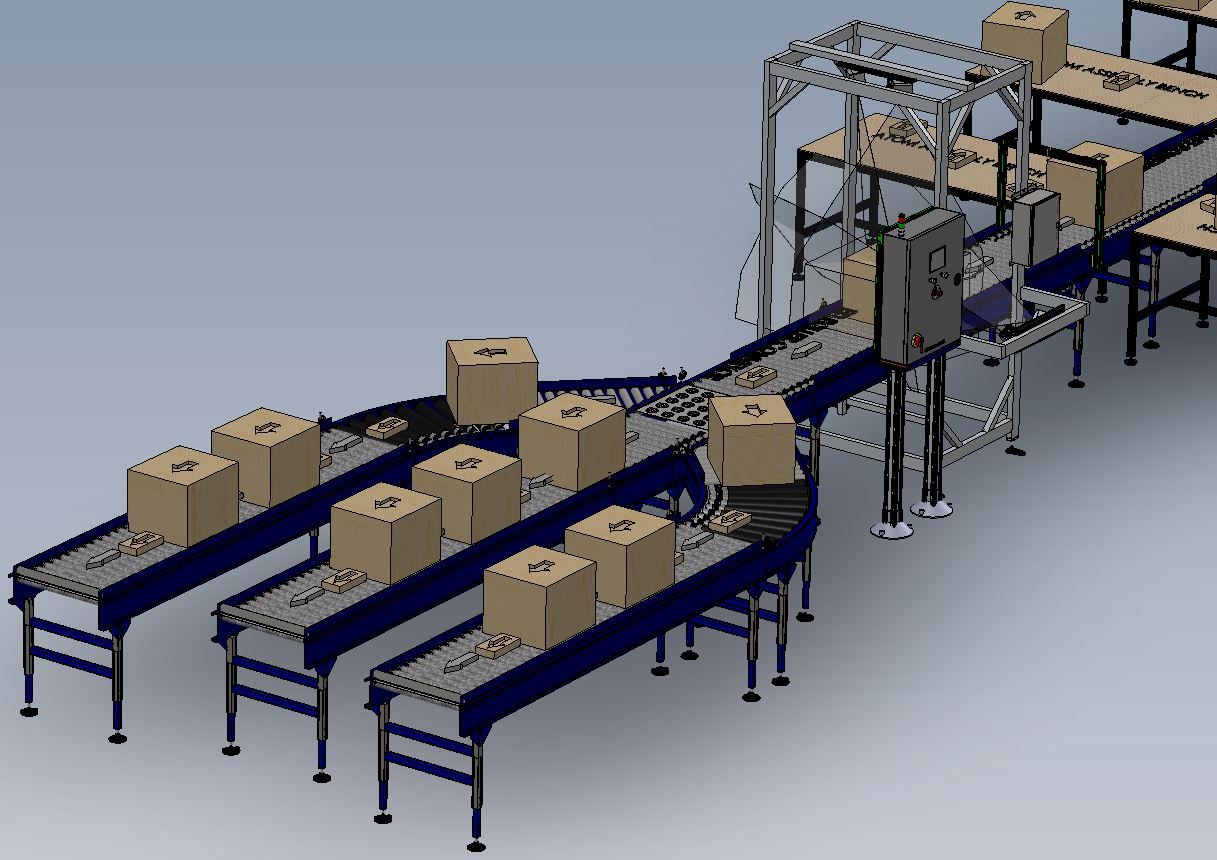

The product is routed using a number of standard options including side belts, diverter arms, air blows and switch sorters as shown in this project. The switch sorter quickly diverts to one of three lanes without slowing the product down.

Touch Screen displays make it easier for operators to run a sortation system. Clear information is displayed and help screens can be added. Fault finding messages make it easier to find problems quickly.

All automated sortation systems are mechanically and electrically installed with full handover and training. Service and maintenance contracts can be provided along with critical spares.