MONK Conveyors pallet systems provide the in-plant transport links between production, warehouse, order picking and despatch. All too often pallets are stored in racks, stacked up and then transported by forklift truck. This can create capacity shortfalls, damage to pallets and products.

The Automotive Industry Pallet System shown below feeds 500kg stillage’s accurately into a metal cleaning process. Bespoke heavy side guides and pneumatic damped stops were design into the system.

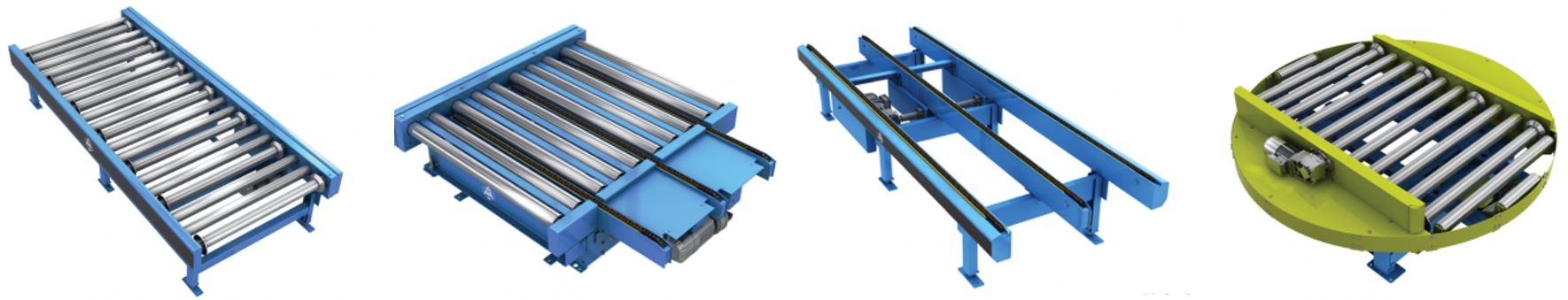

MONK Pallet Conveyors:

- Modular Painted Steel Design

- Up to 1500kg load capacity per meter

- Robust construction with formed steel frame profiles

- 5mm thick steel rollers for impact resistance

- 150mm or 200mm roller pitch

- Motors available – 0.37 kW, 0.55 kW, 1.1 kW and 1.5kW

- Smooth and gentle transportation – minimum backlash, low maintenance design

- Side Chain transfers using bi-directional triple chains

- Roller and Chain rotating turntables

Please Contact Us today to discuss this or any Conveyor System application at +44 (0)1252 369800

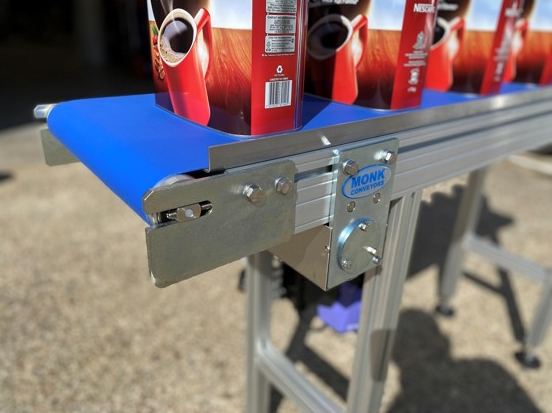

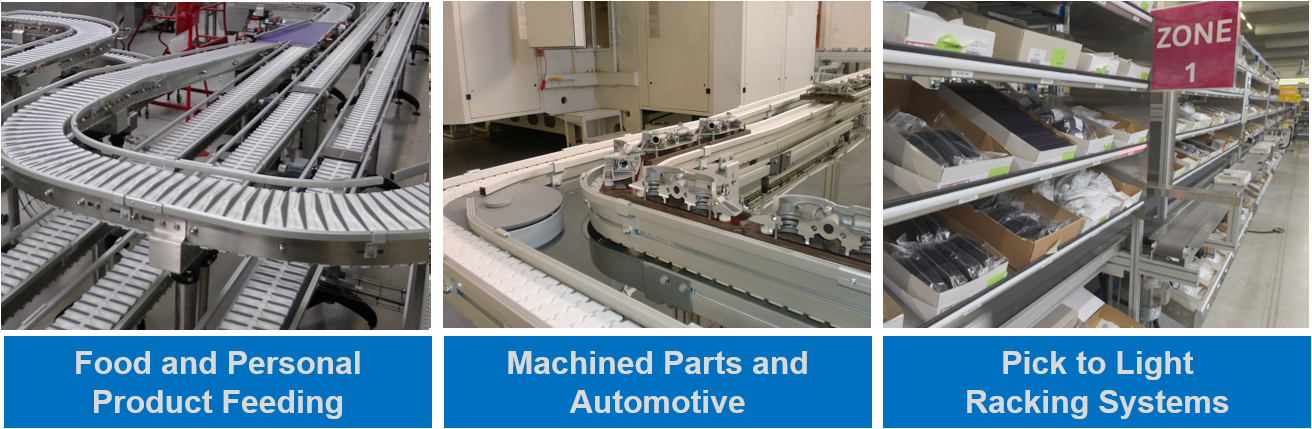

We also supply Roller, Belt and Plastic Chain Conveyors and Product Lifts.

Monk Conveyors supply and install full working systems which are designed to suit your specific needs. We install full pneumatic and electrical control with operator touch screens. Our control systems range from simple stop starts up to barcode capable controls, capable of communicating with your Warehouse Management System (WMS).