MONK’s installation partnership with SICK means we can provide class leading weighing, measuring and product identification conveyors at speeds of up to 6,000 items per hour.

Our in house software capability means we can offer a complete solution including installation, setup and full communications with your warehouse IT system. When each parcel is scanned we will provide: Item measurements (height, width and length), item weight, barcode or QR code information.

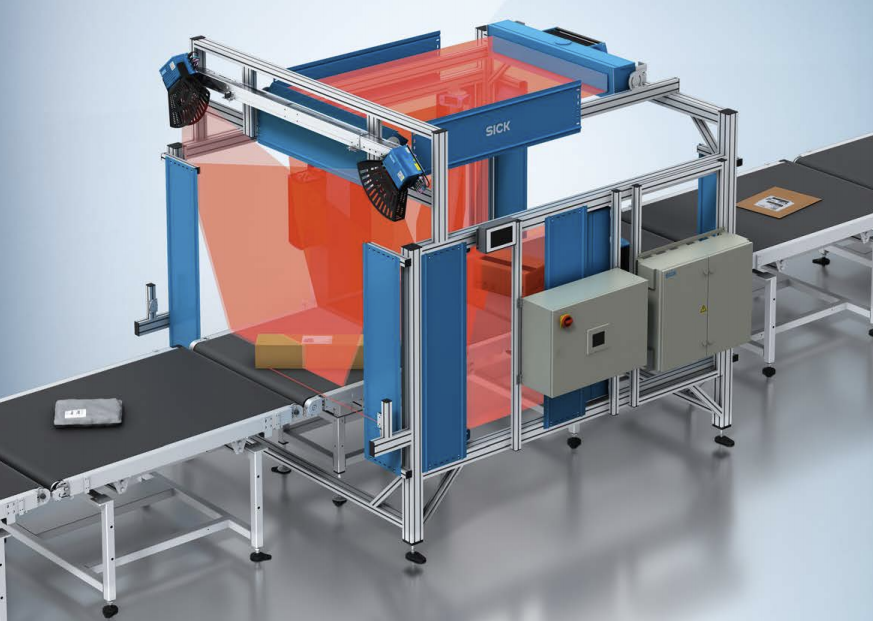

MONK install and setup the SICK DWS Dynamic system, which is the right choice for nearly any master data collection requirement to automate sorting, storage and conveying. The efficient system will improve your data collection along with increasing turnover per parcel. Data can also be used to route parcels to specific areas or bins.

MONK’s high-performance DWS systems from SICK will save time and money. DWS can be integrated into our conveyor system or used as a stand-alone solution. SICK’s modular expansion stages and common system controllers, ensure future-proofing and high system availability.

When simpler system which scan single faces are also provided.

Single Face Scan and Identify

MONK also provide systems which can read a barcodes or QR codes on a single parcel face. This is ideal when parcels can be correctly orientated by staff as they are placed on the system. Parcels can then be routed to the next part of the process.

We supply full electrical control, software and installation.

Monk Conveyors supply and install full working systems which are designed to suit your specific needs. We install full pneumatic and electrical control with operator touch screens if required. Our control systems range from simple stop starts up to barcode capable controls, capable of communicating with your Warehouse Management System (WMS).