News

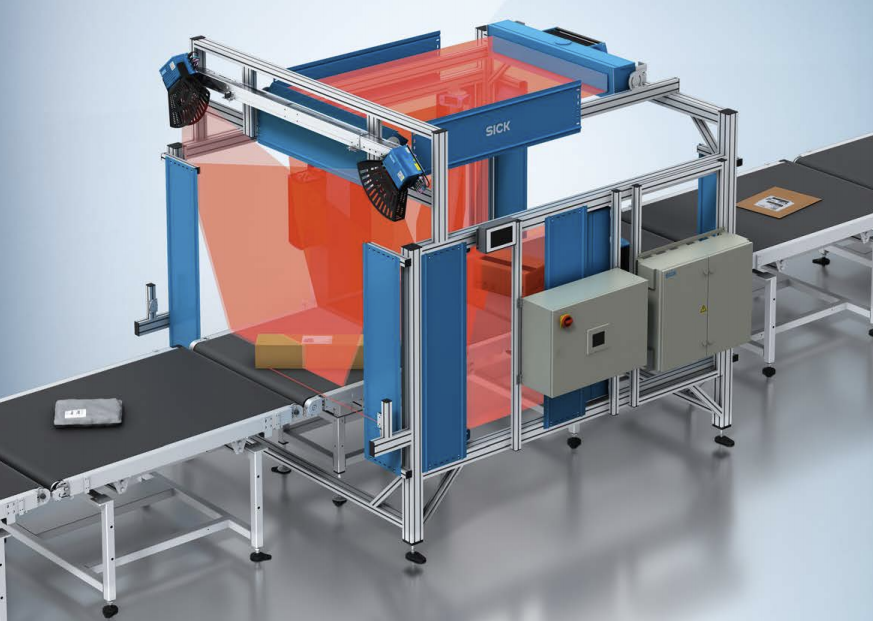

Measure, Weigh & Identify Parcels

MONK’s installation partnership with SICK means we can provide class leading weighing, measuring and product identification conveyors at speeds of […]

> Read MoreWhat is a Powered Conveyor? 60 Second Explainer Video

This short video explains the very basics on different types of conveyors, and how they can save costs and increase […]

> Read MoreWhat is a Spiral Conveyor? – MONK Explainer Video

Our Spiral Conveyor system is a highly efficient way to move products up and down from mezzanine floors or over […]

> Read MoreWhat is MODU Flexible Chain Conveyor?

60 Second Explainer Video MODU flexible chain conveyors are smooth and efficient conveyors, able to transport products across factories with […]

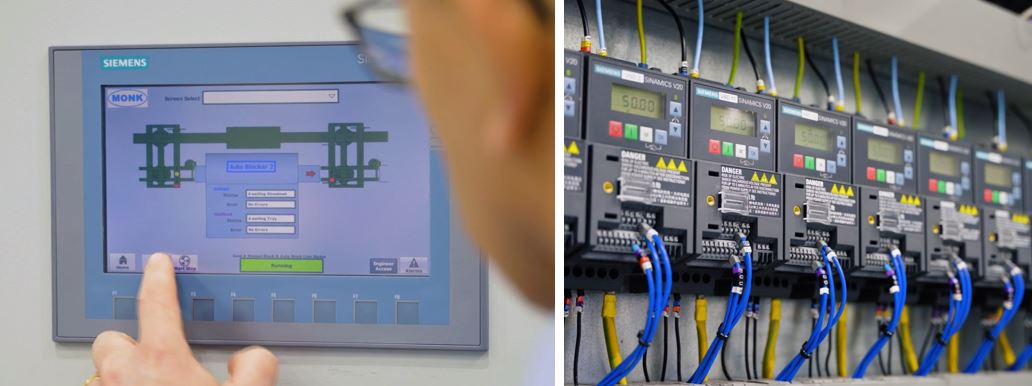

> Read MoreVideo Interview with IFM Electronic

Developing good relationships with suppliers like IFM helps us select the best products and use the latest technology. IFM Electronic […]

> Read MoreConveyor Sortation and Packing Lines Video

The Head of Online Fulfilment for Card Factory explains how efficient Sortation Systems and Packing Lines have helped with the […]

> Read MoreWhat is Pick to Light – 60 Seconds Explainer Video

A Pick to Light System shows staff quickly and efficiently where they should pick from. The system lights up […]

> Read MoreNHS COVID Testing Automation at Southampton University

In October 2020 MONK Conveyors were approached by the University of Southampton to see if we were willing to work […]

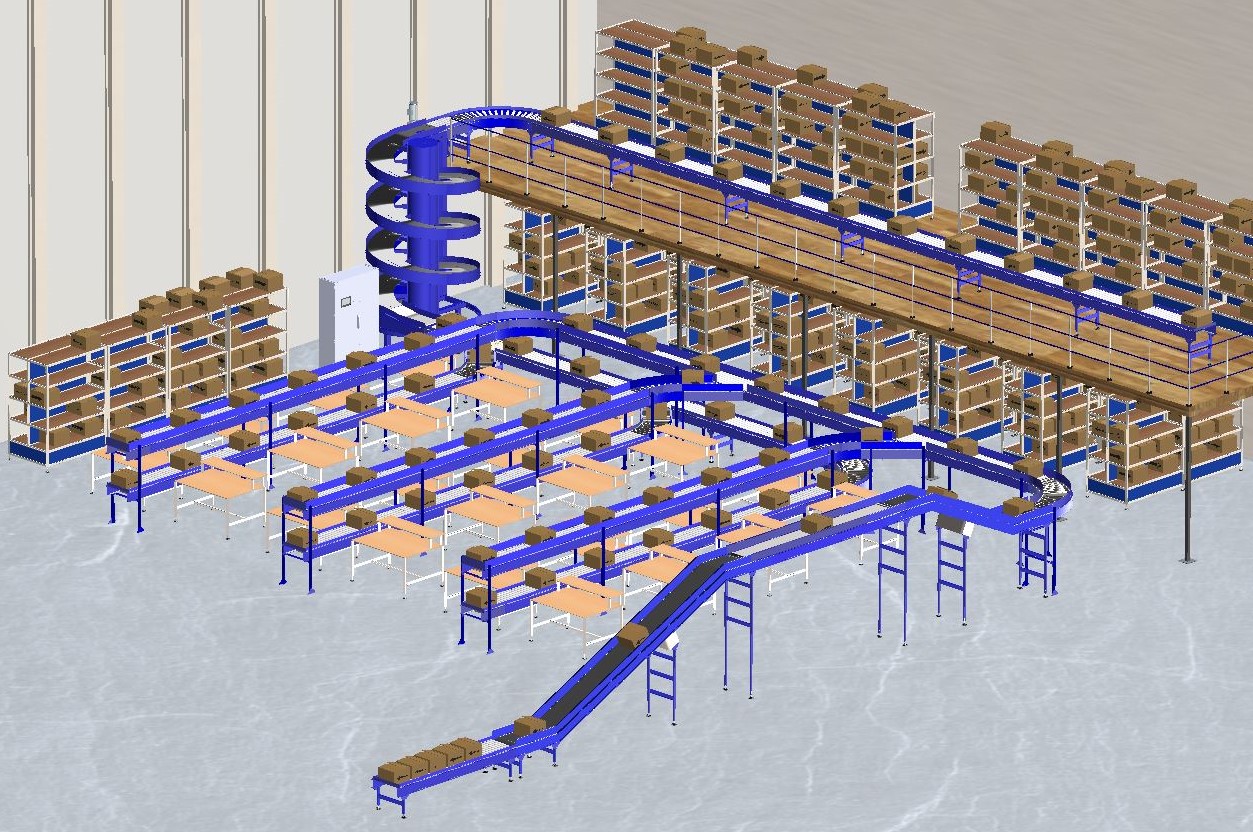

> Read MoreWarehouse Packing and Sortation

MONK have been providing Conveyor Systems and Product handling solutions to a wide range of industries for over 25 years. […]

> Read More